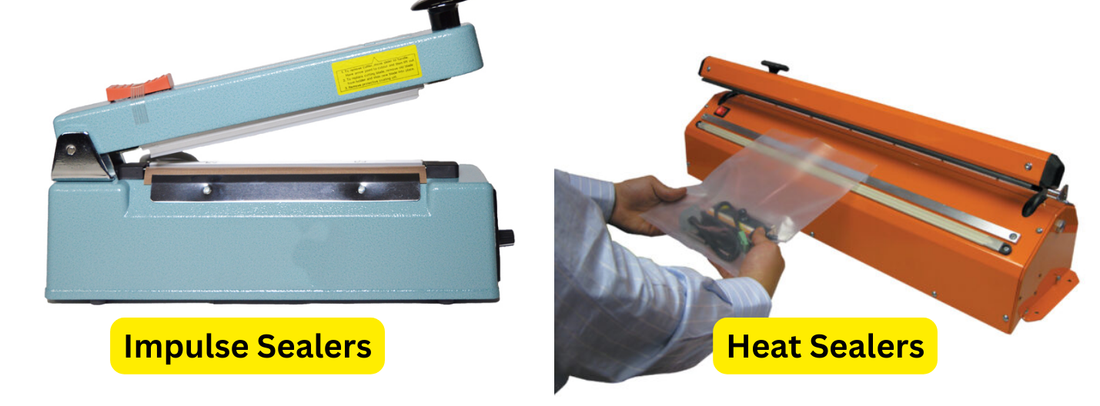

When it comes to packaging, sealing is essential to keep products safe and fresh. Impulse sealers vs heat sealers are two popular methods used for this purpose. Both use heat to join materials together, but they work differently. This article will compare these two methods, helping you understand which one is best for your packaging needs.

Understanding Impulse Sealers: The Quick Burst of Heat

How Impulse Sealers Work

Impulse sealers operate through a simple yet effective mechanism. An electrical impulse heats the sealing wire momentarily, creating a strong seal. Unlike continuous heating methods, impulse sealers feature a cooling phase, meaning the heating element does not remain hot once the seal is made. This approach not only conserves energy but also enhances safety.

Key Advantages of Impulse Sealers

Impulse sealers come with several benefits that make them appealing:

- No Warm-Up Time: Users can enjoy instant readiness, allowing for a smooth workflow in both homes and businesses.

- Energy Efficiency: These devices use power only during the sealing process, contributing to lower energy consumption over time.

- Safety: Since the heating element is not continuously hot, the risk of accidental burns is minimized, making it safer for operators.

- Ease of Use: With straightforward operation, impulse sealers are accessible even for those without extensive training.

- Material Suitability: They are particularly effective for sealing thinner thermoplastic materials like polyethylene (PE) and polypropylene (PP).

Limitations of Impulse Sealers

However, impulse sealers also have their drawbacks:

- Not Ideal for High-Volume Production: For businesses requiring large quantities of packaging, impulse sealers may not keep pace with demand.

- Operator Attention Needed: Achieving optimal results often requires closer attention from the operator, as each seal may vary by user technique.

- Cost Considerations: Certain models can be more expensive upfront, which may not be ideal for tight budgets.

- Material Limitations: They may struggle with very thick or specialty materials, limiting versatility in some applications.

Common Applications of Impulse Sealers

- Impulse sealers are widely used in various situations, including:

- Sealing Poly Bags and Pouches: Perfect for retail and storage needs, keeping products fresh and secure.

- Packaging Food Items: They are extensively used in the food industry for their ability to create airtight seals.

- Small Parts and Retail Goods: Common in small businesses where a professional appearance is desired without extensive machinery.

- Home Use: An excellent choice for DIY enthusiasts who need quick and effective sealing solutions.

Unique features set impulse sealers apart

- Sealing Multi-Layer and Metallized Bags: They can create effective seals for a range of materials, including those with oxygen barriers.

- Cutting Mechanisms: Some models come with built-in cutting capabilities, allowing users to trim excess material easily.

- Portable Options: Handheld and portable impulse sealers are available for specific tasks, lending flexibility to various sealing applications.

Exploring Heat Seals (Constant Heat Sealers): The Steady Approach

How Heat Seals Work

Heat seals operate through a straightforward yet efficient mechanism. They utilize continuously heated jaws that apply constant pressure and heat to the material being sealed. This consistent application allows the edges of the packaging to melt and fuse together. One crucial aspect to consider is the requirement for warm-up time; operators must allow the machine to reach optimal temperature before commencing sealing tasks. This initial step is important for achieving reliable and consistent seals.

Key Advantages of Heat Seals

Heat sealers offer several advantages that make them a preferred choice in many scenarios. Key benefits include:

- Ideal for high-volume sealing – Their continuous operation capability suits environments needing frequent and quick sealing.

- Consistent seals on various materials – Heat seals can adeptly handle a wide array of materials, ensuring uniformity in the sealing process.

- Excellent for thicker or laminated materials – They perform exceptionally well with thicker materials, including foils and cellophanes, which may be challenging for other sealing methods.

- Less operator attention in automated setups – In automated systems, heat sealers require minimal oversight, allowing operators to focus on other tasks.

Limitations of Heat Seals

Despite their advantages, heat seals are not without drawbacks. Consider these limitations:

- Warm-up time is necessary – Prolonged preheating can extend downtime, especially if not properly planned.

- Higher energy consumption – Continuous heating leads to increased energy usage, which may impact operational costs.

- Greater initial investment – Generally, heat seal machines are more expensive to purchase compared to other types.

- Material limitations – Not all plastics are suitable for heat sealing; for instance, polyethylene may present challenges due to its low melting point.

Common Applications of Heat Seals

Heat seals are utilized across diverse sectors, highlighting their versatility. Common applications include:

- Sealing foil pouches – Ideal for products requiring moisture and light protection.

- Gusset bags and laminated materials – Perfect for packaging snacks and other food items.

- Pharmaceutical and food processing industries – Their robust sealing capabilities are crucial in these sectors for maintaining product integrity.

In addition to their standard functions, heat seal machines can possess rare and valuable attributes:

- Features like date coding and gas flushing – These specialized functions can enhance the shelf life and traceability of the product.

- Specialized types such as band sealers – These machines cater to very high throughput needs, ensuring efficient processing in large-scale applications.

- Use in sterile environments – Heat seals are reliable for applications requiring strong seals, such as in medical device packaging.

How to Heat Seal Poly Bags: Complete Guide

Key Differences Summarized: Impulse vs. Heat Seal

Heating Mechanism

- Impulse – Utilizes a short burst of heat to seal the material, requiring less energy and resulting in lower thermal stress on the product.

- Heat – Relies on a constant heat application, allowing for robust bonding but demanding a watchful eye on energy use.

Material Compatibility

- Impulse – Best suited for thinner thermoplastics, such as polyethylene (PE) and polypropylene (PP).

- Heat – Better equipped to handle thicker, laminated, and foil materials thanks to its constant heat application.

Speed and Volume

- Impulse – Generally suitable for low to medium-volume operations; perfect for smaller projects where efficiency is key.

- Heat – Designed for medium to high-volume sealing, making it the workhorse of packaging environments.

Energy Consumption

- Impulse – Typically characterized by lower energy consumption, appealing for businesses watching their operational costs.

- Heat – Higher energy demands due to the constant heating process, which may lead to increased expenses over time.

Cost

- Impulse – Often features a lower initial cost for basic models, making it accessible for smaller businesses or startups.

- Heat – Generally entails a higher initial investment, reflecting its capabilities in high-volume applications.

Safety

- Impulse – Safer as it involves intermittent heating, reducing the risk of burns or fire hazards.

- Heat – Requires more caution due to constantly hot surfaces, which can pose a safety risk to operators.

Choosing the Right Sealer for Your Needs

Consider the Material You Need to Seal

Choosing the right sealer starts with understanding the materials you are working with. Impulse sealers work best with thin to medium plastic materials. They are excellent for polyethylene and polypropylene, which are common in many packaging applications.

On the other hand, heat sealers can handle a wider variety of materials, including thicker plastics and multi-layered pouches. This makes them more versatile in different industrial settings, particularly when dealing with materials like foil.

Tip: Always check the specifications of the sealer to ensure it’s compatible with the material you intend to use.

Evaluate Your Production Volume

Production volume is another critical factor. If your operation involves high production rates, a heat sealer, such as a band sealer, may be the better choice. These machines are designed for continuous operation and can process large quantities efficiently, making them ideal for factories and large-scale packaging operations.

Conversely, impulse sealers are perfect for smaller batches. They provide flexibility and ease of use without needing significant space or capital investment. Thus, if your business requires low to moderate production capabilities, an impulse sealer can serve you well without overwhelming costs.

Think About Your Budget

Pricing often dictates the choice of sealing equipment. Impulse sealers are generally more affordable upfront and can be a good starting point for small or home-based businesses. They require a lower initial investment, which can be appealing for entrepreneurs just beginning to explore packaging solutions.

Heat sealers typically have a higher price tag due to their more complex design and capability for heavy-duty use. However, considering their durability and efficiency in high-volume applications, they may offer a better return on investment over time.

Assess the Required Seal Strength and Integrity

The desired strength and integrity of seals will greatly influence your decision. Impulse sealers create a strong seal by using a burst of heat generated briefly, making them suitable for applications where moderate seal strength is acceptable.

In contrast, heat sealers provide a more uniform and often stronger seal, which is essential for products requiring long shelf life or secure packaging during shipping. Industries like food and pharmaceuticals often prioritize seal strength to ensure product safety and freshness, making heat sealers the preferred option.

Consider Ease of Use and Maintenance

User-friendliness is an essential consideration when investing in sealing equipment. Impulse sealers are generally easy to operate, requiring minimal training. Their simple on-and-off operation makes them ideal for businesses with a diverse workforce, from full-time employees to temporary staff.

Heat sealers, while effective, may require more extensive maintenance and operational know-how, particularly in high-volume settings. Regular cleaning and calibration are necessary to maintain performance and efficiency. It’s important to weigh the time and effort needed for maintenance against your production requirements.

Conclusion

In summary, both impulse sealers and heat sealers have distinct advantages and disadvantages that cater to different needs. Impulse sealers are perfect for low to moderate production volumes, ease of use, and budget-conscious buyers, while heat sealers are better suited for high-volume operations requiring strong, reliable seals.

As you consider your specific requirements, take the time to assess your material types, production rates, budget constraints, and seal strength needs. This thoughtful approach will help you choose the right sealer that aligns with your operational goals.

Frequently Asked Questions (FAQ)

Q1: Can an impulse sealer be used for thick bags?

A: Generally, impulse sealers are better suited for thinner materials. For thicker bags, a heat sealer might be more effective.

Q2: Is a heat sealer better for continuous use?

A: Yes, heat sealers (especially band sealers) are designed for continuous operation and high production volumes.

Q3: Which type of sealer is more energy-efficient?

A: Impulse sealers are generally more energy-efficient as they only use power during the sealing process.

Q4: Can I seal foil pouches with an impulse sealer?

A: While some advanced impulse sealers can handle certain types of foil pouches, heat sealers are typically recommended for consistent sealing of foil materials.