PBAT (Polybutylene Adipate Terephthalate) is a biodegradable and compostable plastic known for its flexibility and toughness, making it a viable alternative to conventional plastics. With increasing global concerns regarding plastic pollution, materials like PBAT are gaining attention for their potential to transform the packaging landscape.

Relevance in Sustainable Packaging: As the demand for eco-friendly materials grows, PBAT's properties position it as a key player in reducing plastic waste in the packaging industry. Companies are increasingly looking for alternatives that do not compromise on performance while also minimizing environmental impact. PBAT offers a solution that aligns with the sustainability goals of businesses and consumers alike.

What is bioplastic? How does biodegradable plastic help the environment?

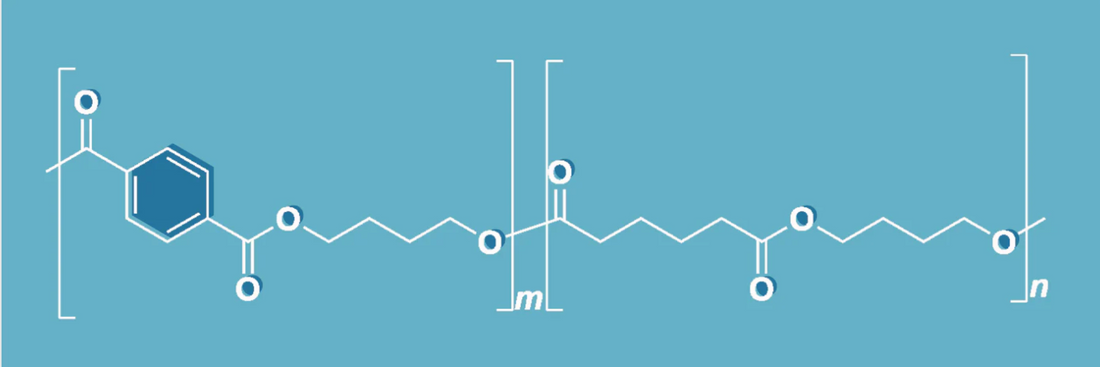

Chemical Structure and Properties of PBAT

Chemical Composition: PBAT is a copolyester derived from adipic acid, 1,4-butanediol, and terephthalic acid, resulting in a random copolymer structure. This unique composition provides a blend of properties that make PBAT suitable for various applications.

Physical Properties:

- Flexibility and Toughness: PBAT exhibits properties similar to low-density polyethylene (LDPE), offering high flexibility and resilience, essential for applications requiring durable and pliable materials.

- Melting Point: It possesses a wide melting point range due to its random structure, enabling it to maintain performance across various temperature conditions.

- Mechanical Strength: Combining flexibility with notable tensile strength, PBAT is suitable for diverse applications, ensuring that it can withstand everyday use while still being environmentally friendly.

Production Process of PBAT

Synthesis: PBAT is produced through the polycondensation of adipic acid, 1,4-butanediol, and terephthalic acid. This chemical reaction is vital in creating the polymer's unique characteristics that lend to its biodegradability.

Raw Materials: Traditionally, the raw materials for PBAT are sourced from petrochemical derivatives, raising concerns about sustainability. However, advancements are being made to utilize renewable resources, aligning the production process with eco-friendly practices.

Environmental Benefits of PBAT

- Biodegradability: PBAT can decompose under industrial composting conditions, significantly reducing its long-term environmental impact compared to conventional plastics.

- Compostability: It is suitable for composting, breaking down into water, carbon dioxide, and biomass without leaving harmful residues. This is particularly important for reducing landfill waste.

- Reduction of Plastic Waste: By offering an alternative to traditional plastics, PBAT contributes to decreased pollution and landfill usage, making it a vital material in the fight against plastic waste.

Applications of PBAT in Packaging

- Flexible Packaging: PBAT is utilized in producing biodegradable bags, wraps, and films for food and consumer goods, allowing for packaging that is both functional and sustainable.

- Agricultural Films: Applied in mulch films and greenhouse coverings that degrade after use, PBAT helps in minimizing agricultural waste, providing a dual benefit of utility and environmental protection.

- Disposable Products: It is manufactured into compostable cutlery, plates, and cups for the food service industry, offering a sustainable alternative that meets consumer demands for eco-friendly disposable products.

Comparing PBAT with Other Biodegradable Plastics

PBAT vs. PLA (Polylactic Acid):

- Flexibility: PBAT is more flexible, while PLA tends to be more rigid, making PBAT preferable for applications requiring higher durability.

- Degradation Rate: PBAT generally degrades faster under composting conditions compared to PLA, enhancing its environmental appeal.

PBAT vs. PHA (Polyhydroxyalkanoates):

- Mechanical Properties: PBAT offers better mechanical strength and processability than PHA, making it a more versatile choice for manufacturers.

- Cost: PBAT is often more cost-effective due to established production processes, encouraging its adoption across various industries.

Challenges and Limitations of PBAT

- Feedstock Sourcing: The dependence on petrochemical sources raises sustainability concerns; ongoing research aims to incorporate bio-based alternatives that reduce this reliance.

- Composting Infrastructure: Effective degradation requires industrial composting facilities, which may not be widely available, limiting the material's real-world impact.

- Cost Considerations: Higher production costs compared to conventional plastics can impact market adoption, necessitating a focus on cost-reduction strategies.

Future Outlook for PBAT in Sustainable Packaging

- Technological Advancements: Innovations in bio-based feedstocks and production efficiency are enhancing PBAT's sustainability profile, making it a more attractive option for manufacturers.

- Market Trends: Growing consumer awareness and regulatory pressures are driving increased adoption of biodegradable plastics like PBAT, signaling a shift towards sustainable solutions.

- Research and Development: Ongoing studies focus on improving PBAT's properties and expanding its application range, ensuring that it continues to meet the evolving needs of the market.

Conclusion

PBAT stands as a promising biodegradable polymer offering significant environmental benefits and versatile applications in sustainable packaging. By understanding its properties, production, and challenges, stakeholders can better leverage PBAT to contribute to a more sustainable future. As the world moves toward more environmentally friendly alternatives, PBAT represents a crucial step in reducing plastic waste and fostering a healthier planet.